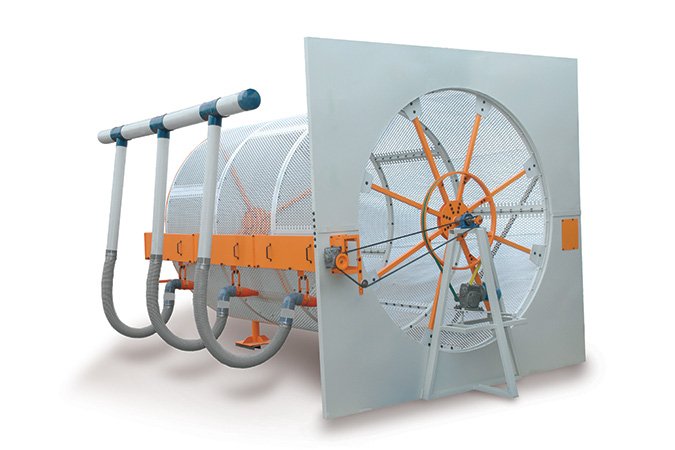

Rotary Drum Filter

Maintaining a clean environment is essential for enhancing performance and productivity, particularly in textile mills, where airborne dust and fiber fly can significantly affect yarn quality. To address this challenge, Coimbatore Air Control Systems has developed a Rotary Drum Filter engineered for high filtration efficiency and minimal maintenance.

The filter assembly features perforated mild steel (MS) sheets supported by a sturdy MS framework. It is powered by a 0.5 HP gear motor, while the suction nozzle is connected to a 5 HP high-pressure suction fan for effective dust extraction.

Collected dust is discharged into a cyclone compactor, collection bag, or screw compactor, depending on the system configuration.

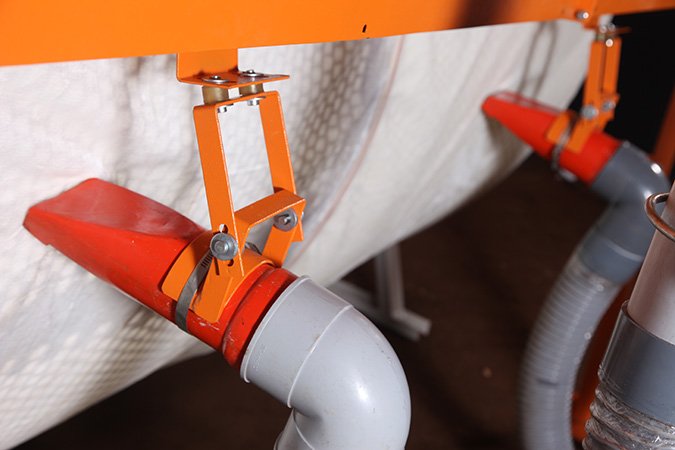

The linear motion of the suction nozzle is precisely synchronized with the drum’s rotation to ensure uniform cleaning. The nozzle itself is specially designed to maintain optimal suction pressure throughout operation.

A synthetic filter media is mounted on the surface of the rotary drum, enabling efficient removal of cotton fibers and dust from departments or exhaust trenches. This design ensures high filtration performance with low pressure drop, contributing to cleaner air and improved operational outcomes.